Продукция

-

Efficient Ball valve Grinding Machine for Valve Industry

-

Малый обрабатывающий центр с ЧПУ VMC640

-

DHM50 Горизонтальный обрабатывающий центр

-

China factory Big Spindle Bore Cnc Pipe Thread Lathe Qk1319 Pipe Threading Machine

-

RC926 Токарный станок с ЧПУ швейцарского типа

-

VT600 автоматический токарный станок с чпу

-

Токарный станок с наклонной станиной TCK46A

-

Токарный станок с ЧПУ TCK50A

-

Высокая точность VMC1370 графитовый фрезерный обрабатывающий центр с чпу

-

GMF3015B Портальный обрабатывающий центр

-

Немецкий малогабаритный токарный станок с ЧПУ HT2

-

VMC640 фрезерный станок с ЧПУ

-

VMC1680 Большой обрабатывающий центр

-

VMC1055 обрабатывающий центр

-

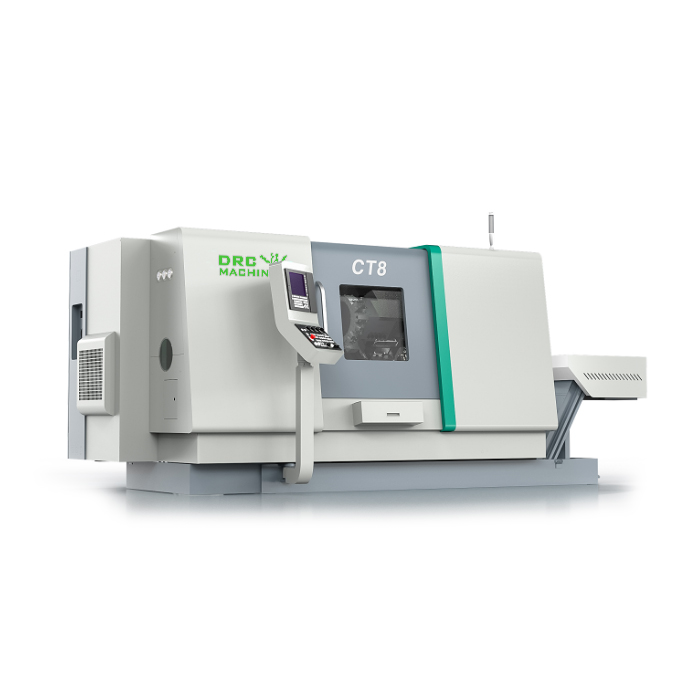

CT8 с чпу торно-токарный 4- осевой универсальный поворотный центр

-

CK1107 Токарный станок с ЧПУ швейцарского типа

Станок для сверления глубоких отверстий

High Quality Deep Hole Gun Drilling Machine RC2135 BTA Deep Hole Drilling and Boring Machine for Blind Hole

Описание

маркер

High Quality Deep Hole Gun Drilling Machine RC2135 BTA Deep Hole Drilling and Boring Machine for Blind Hole

TS2120/TS2135 deep hole drilling and boring machine This machine tool is a special equipment for processing cylindrical deep hole workpieces, such as the spindle hole of the machine tool, various mechanical hydraulic cylinders, cylindrical through holes, blind holes and stepped holes.

Machine use: Specialized in machining cylindrical deep hole workpieces. Such as the spindle hole of the machine tool, various mechanical hydraulic cylinders, cylindrical through holes, blind holes and stepped holes. The machine tool can not only undertake drilling, boring, but also rolling processing. The internal chip removal method is used when drilling. The machine bed has strong rigidity and good precision retention. The spindle speed has a wide range, and the feed system is driven by an AC servo motor, which can meet the needs of various deep hole machining processes. Hydraulic device is used for the tightening of the oil dispenser and the tightening of the workpiece, and the instrument display is safe and reliable. This machine tool is a series of products, and can also provide various deformation products according to customer needs.

Machine main parts: Machine bed , headstock, oil pressure head, one set drill bar support rest, sliding guide rail, rack and pinion, coolant system, DELTA PLC control system, electric cabinet, one set center rest and so on . Workpiece clamping One end of the workpiece is clamped by the manual three-jaw chuck of headstock , oil pressure head tighten another end automatically(workpiece OD chamfer 4X30°), center rest support the workpiece . The gears are machined by precision grinding , gear surface is quenched by high frequency quenching, and the hardness of the tooth surface is HRC48-52, so that the gear can obtain high strength, high hardness, high wear resistance and high fatigue limit, and can withstand relatively large alternating load and shock load. In order to improve the service life of gears and bearings, lubricating oil is used to circulate lubrication.

Center rest Used for supporting the workpiece; Three-point closed type center rest structure, two rollers below, and one roller on the top; The lateral position of two rollers below is adjusted by screw . Drill bar support rest Used for supporting the drill bar ; A high rigidity integral structure is adopted, on which a support sleeve is assembled, which can absorb the shock and vibration produced during machining and so on .

Specification

| Scope of work ——————— — —— TS2120 —— —————— TS2135 | other parts |

| Drilling diameter range——Φ40~Φ80mm——Φ40~Φ80mm | Rail width ——650mm——650mm |

| Boring diameter range—Φ40~Φ200mm—Φ40~Φ350mm | Rated pressure of cooling system——2.5MPa——2.5MPa |

| Maximum depth of boring——————1-16m (one size per meter)——1-16m (one size per meter) | Cooling system flow——————100, 200, 300, 400L/min——100, 200, 300, 400L/min |

| Nest diameter range——Φ80~Φ150mm——Φ80~Φ180mm | Rated working pressure of hydraulic system——6.3MPa———6.3MPa |

| Workholding diameter range————Φ60~Φ300mm——————Φ100~Φ400mm | The oil dispenser bears the maximum axial force——68kN——68kN |

| Spindle part | The maximum tightening force of the oil dispenser to the workpiece—20 kN——20 kN |

| Spindle center height ——350mm——450mm | Drill pipe box part (optional) |

| Headstock spindle aperture ——Φ75mm——Φ75mm | Drill pipe box spindle diameter ——Φ75mm——Φ75mm |

| Taper hole at the front end of the headstock spindle————Φ85 1:20—————————Φ85 1:20 | Taper hole at the front end of the spindle of the drill pipe box——Φ85mm 1:20———Φ85mm 1:20 |

| Headstock spindle speed range————60~1000r/min ——————42~670r/min; 12 grades | Drill pipe box spindle speed range——60~1000r/min;12 grades————42~670r/min;12 grades |

| feed section | Drill pipe box motor power ——15KW——15KW |

| Feed speed range——5-300mm/min——5-300mm/min | |

| Fast moving speed of pallet———2m/min——2m/min | |

| Motor part | |

| Main motor power——————30kW——————30kW | |

| Hydraulic pump motor power ——1.5kW——1.5kW | |

| Fast moving motor power ——3 kW——3 kW | |

| Feed motor power——4.7kW (servo motor)——4.7kW (servo motor) | |

| Cooling pump motor power ——5.5kWX4group——5.5kWX4group | |

Following items should be ordered separately according to your needed size: